During the use of the hydraulic cylinder, the problem of seal failure often occurs, which affects the normal work. The damage of the hydraulic cylinder seal is the main reason for the failure of the seal.

1) Seal surfaces worn. During the operation of the hydraulic cylinder, the friction between the seal and the metal surface is caused by sliding, which is easy to cause the seal to wear. Impurities in the oil, especially metal particles, or excessive surface roughness of the metal and too tight packing can exacerbate this situation.

2) The problem of extrusion deformation. An inevitable practical problem is that when there is high pressure, the seal of the hydraulic cylinder is prone to liquefaction, and then enters the gap of the sealing surface. When the hydraulic cylinder seal moves relative to the sealing groove, it is more conducive to the occurrence of this problem, and the gap extrusion causes the seal to be completely damaged, even the surface is broken, or plastic deformation. If you want to avoid this problem, you can add a sealing ring.

3) There is also the flipping problem. When the hydraulic equipment is in operation, it will cause a lot of pressure in the sealing groove. Under the action of the pressure, the bottom of the hydraulic cylinder seal is very easy to be worn, and then the seal is turned over under the action of friction and removed from the seal. The sealing groove is protruded, the sealing lip is cut or crushed, and the seal is completely damaged.

4) In addition, there is a very common phenomenon called eccentric wear, which is also one of the main reasons for the damage of hydraulic cylinder seals. Due to the original problem of the seal, or the eccentricity of the sealing support surface, it may also be due to partial burrs on the mating surface of the reciprocating element and the seal and radial loads, etc., which will cause eccentric wear.

5) Material aging. Due to long use time or long storage time, the hydraulic cylinder seals are oxidized and become harder and brittle, losing their original elasticity and thus losing their sealing performance.

6) Tolerance reasons

The correct assembly tolerance is necessary for the installation of the cylinder seal, and the shaft (sleeve) must have the appropriate surface roughness and the correct size. This requires that the dimensional accuracy and geometric tolerance of the seal must meet the requirements of the drawing, otherwise it will easily lead to premature failure of the seal.

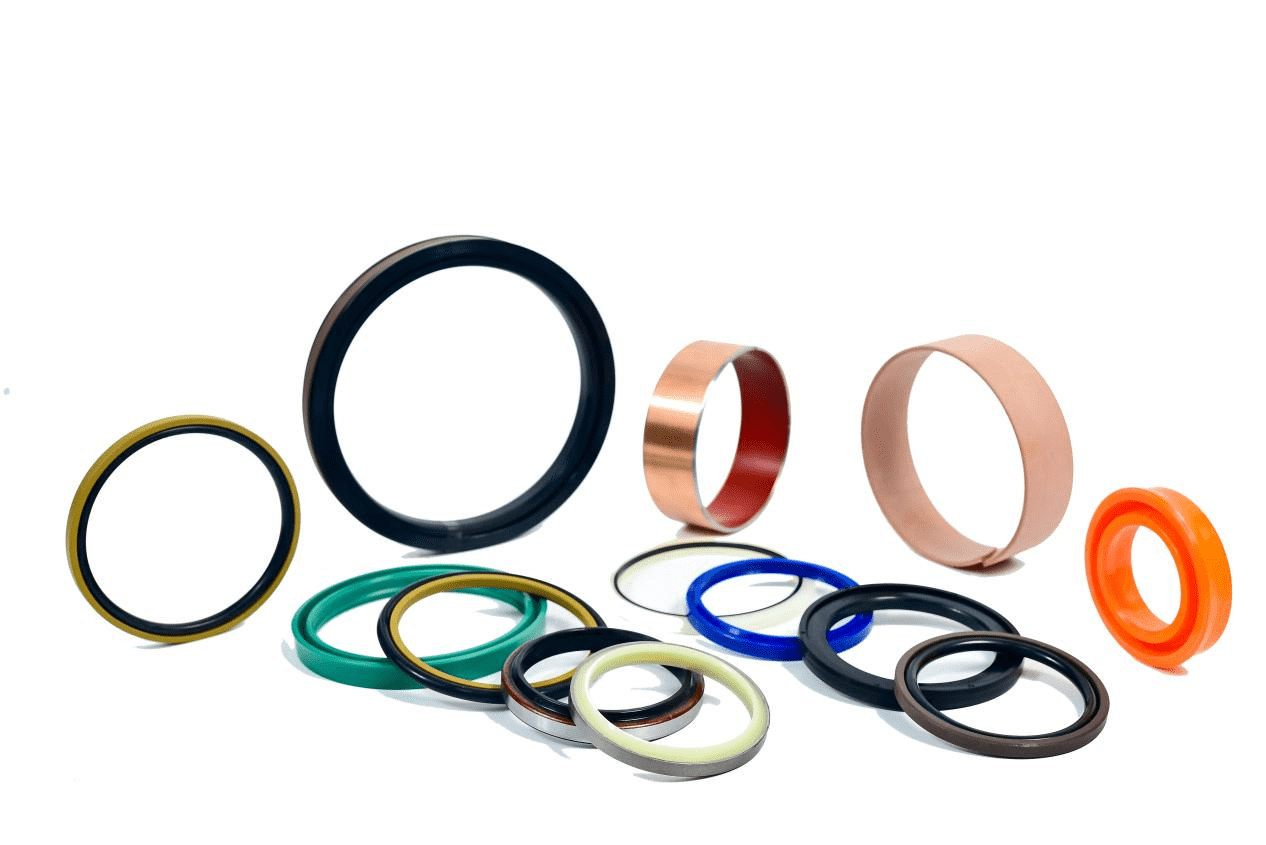

The above are the reasons for the failure of the cylinder seals. I believe you can better understand the mechanical seals after understanding them. Our company is a professional manufacturer of seals, if you want to buy seals, you can contact us.The above are the three reasons for the failure of mechanical seals. I believe you can better understand mechanical seals after understanding them. Our company is a professional manufacturer of seals, if you want to buy seals, you can contact us.

Post time: Mar-16-2022